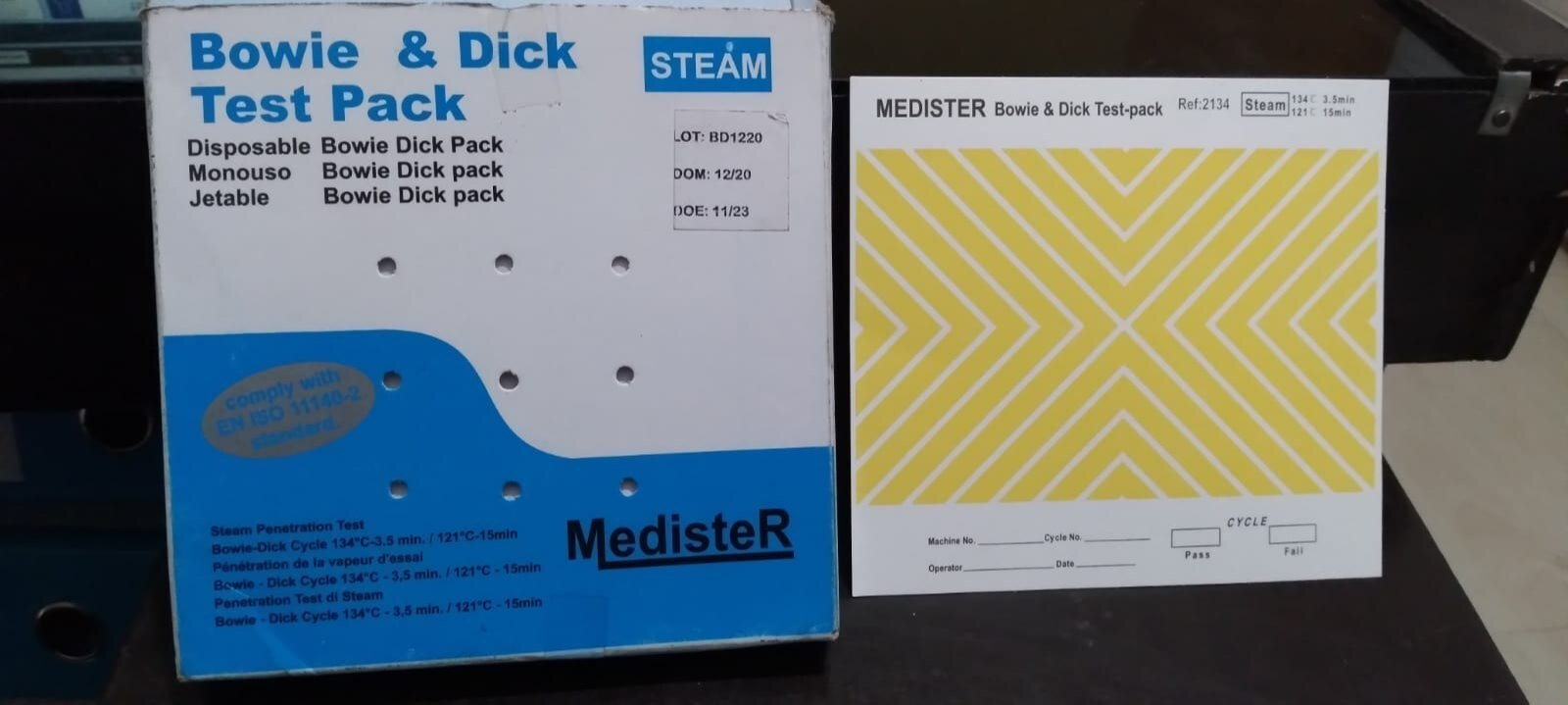

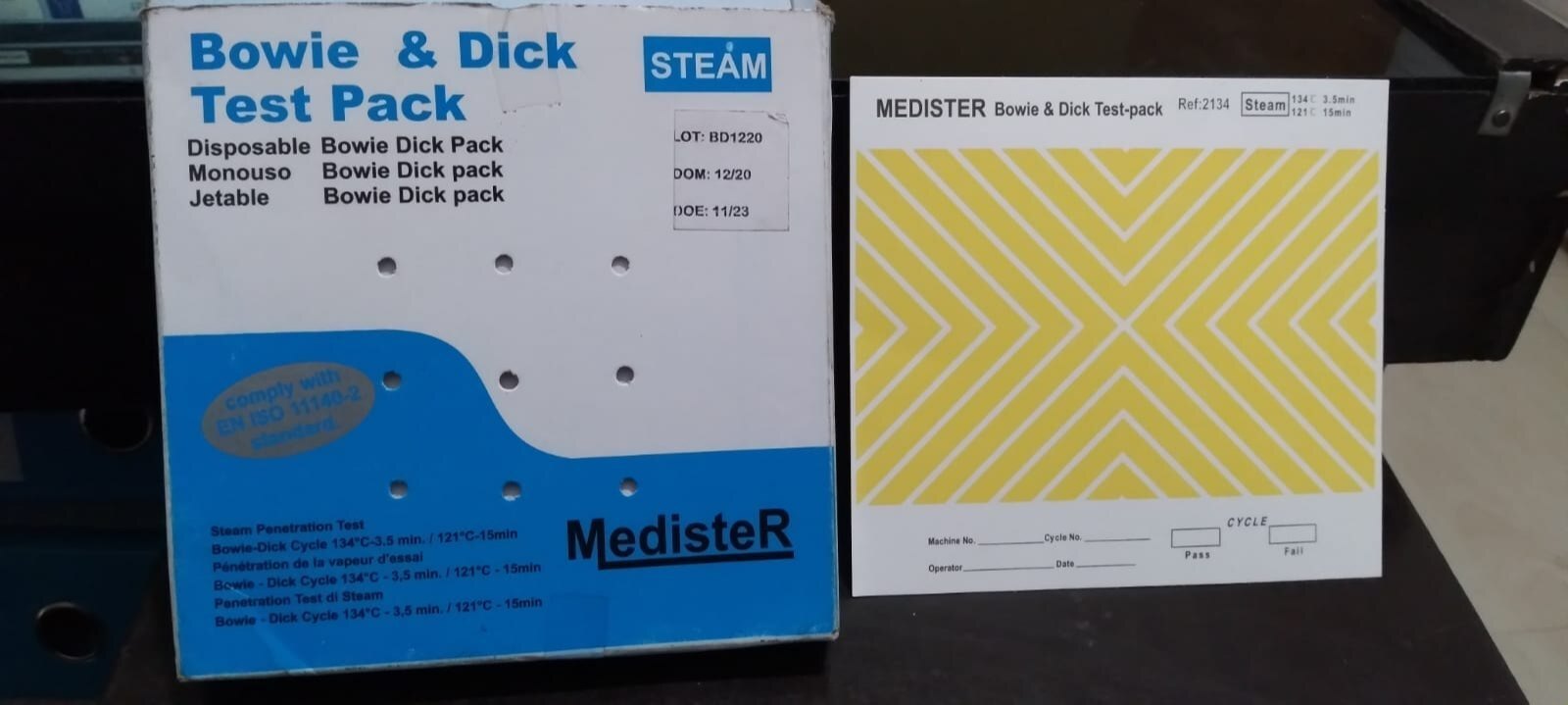

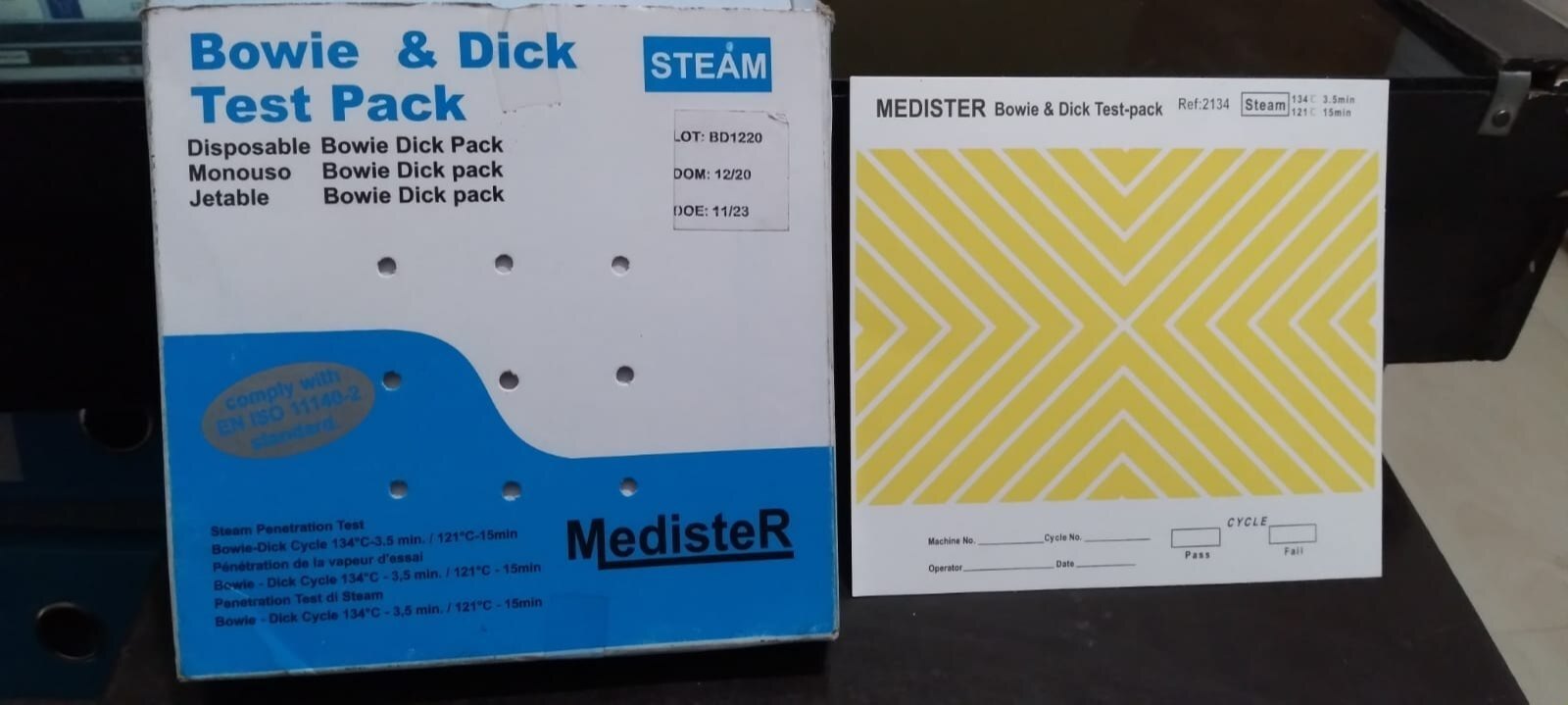

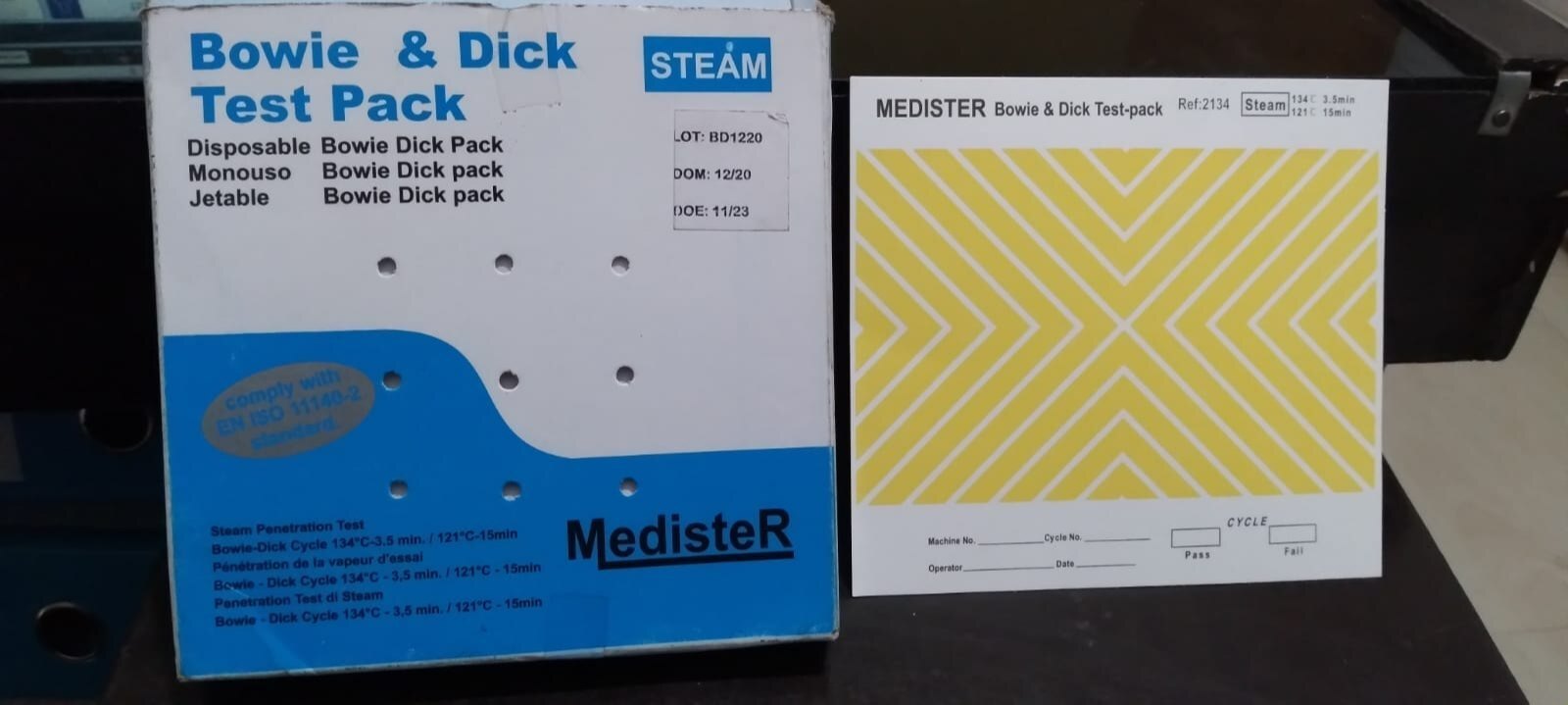

Bowie Dick Test Pack k

Bowie Dick Test Pack k Specification

- Display Type

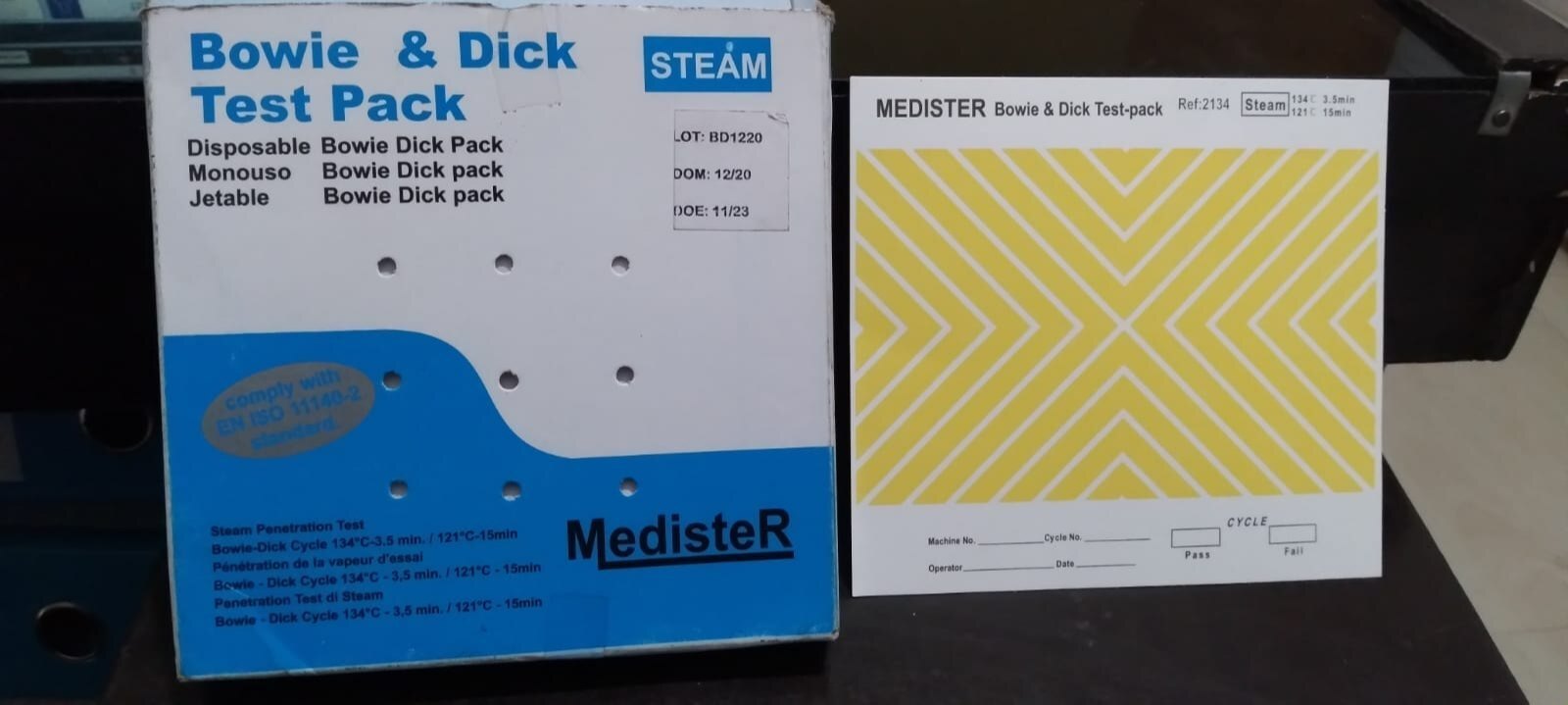

- Visual color change

- Shelf Life

- 36 months

- Storage Instructions

- Store in a cool, dry place away from direct sunlight

- Features

- Immediate visual result, standardized test sheet, clear color change

- Instruments Type

- Sterilization process indicator

- Function

- Checks the efficacy of steam sterilization process

- Accuracy

- Reliable visual confirmation

- Frequency

- Daily or as recommended

- Usage Type

- Single use

- Equipment Type

- Bowie Dick Test Pack

- Material

- Paper board and chemical indicator sheet

- Condition

- New

- Technology

- Chemical Indicator

- Portable

- Yes

- Wall Mounted

- No

- Real-Time Operation

- Yes

- Operating Type

- Manual

- Use

- Testing steam penetration and air removal efficiency in autoclaves

- Dimension (L*W*H)

- Approx. 120mm x 125mm x 18mm

- Weight

- Approx. 100 g

- Color

- White with indicator sheet

- Application Area

- CSSD, hospitals, clinics, laboratories

- Compliance

- ISO certified

- Indicator Type

- Bowie Dick simulation

- Disposability

- Disposable after use

- Result Interpretation

- Distinct color change indicates pass or fail

- Sterilization Cycle Compatibility

- Pre-vacuum steam sterilizers at 134°C for 3.5 minutes

- Packaging

- Individual pack, sealed

- Expiry Date Mentioned

- Yes on every pack

- Test Standard

- Conforms to EN ISO 11140-4

About Bowie Dick Test Pack k

- Home /

- Healthcare /

- Knowledge Center /

- Sterile Processing /

- Bowie-Dick Tests and Troubleshooting Guide

January 8, 2020

To fully answer why this test is still important today, we must first understand why it is important to remove air from the sterilizer. Air within a steam sterilizer is often referred to as a non-condensable gas (NCG). As the name indicates, non-condensable gases do not condense when touching a colder item. These gases act like a shield between the steam and the item, potentially shielding bacteria and preventing proper sterilization.

Even todays sterilizers are not capable of detecting NCG because it could be hiding anywhere in the chamber. Sensors would need to be placed within the packs exactly where the NCG would either be trapped or collected in order to detect it. This is not possible and supports why air-removal tests are still very relevant to todays modern sterilizers for autoclave testing. The Vacuum Leak Test programmed on your autoclaved only measures the integrity of the sealed pressure vessel and associated piping to assure air is not being admitted to the sterilizer during the vacuum draw downs.

In addition to air-removal, modern Bowie-Dick Tests such as the VERIFY Bowie-Dick Test Pack provide a critical control for sterilizer performance and verification of steam quality. It ensures the sterilizer can provide the validated preconditioning required, and aid in detection of steam quality that could interfere with sterilization of complex instrumentation.

Immediate and Reliable Results

This Bowie Dick Test Pack provides instant visual confirmation of your autoclave's performance. The clear color change on the indicator sheet allows for easy pass or fail interpretation, ensuring any issues with steam penetration or air removal are quickly identified and rectified.

Easy and Convenient Operation

Designed to be user-friendly, simply place the test pack into the sterilizer for a cycle at 134C for 3.5 minutes. After completion, examine the indicator sheet for the result. Its portable, disposable nature and handy size make it suitable for daily use in busy clinical environments.

Strict Compliance and Quality Assurance

Conforming to EN ISO 11140-4 standards and ISO certified, each pack ensures you meet regulatory quality assurance practices. Every unit is clearly marked with an expiry date, assuring effective performance through its 36-month shelf life when stored under recommended conditions.

FAQ's of Bowie Dick Test Pack ka1:

Q: How should the Bowie Dick Test Pack be used for optimal results?

A: Place the test pack in an empty pre-vacuum steam sterilizer chamber and run a cycle at 134C for 3.5 minutes. After the cycle, check the indicator sheet for a distinct color change. A complete, uniform color change means the sterilizer has passed.Q: What does a color change in the indicator sheet signify?

A: A distinct color change on the indicator sheet indicates the presence of sufficient steam penetration and air removal, confirming a successful sterilization cycle. Lack of uniform color change signals a potential issue with the autoclave process.Q: When and how often should the Bowie Dick Test Pack be utilized?

A: It is recommended to use the test pack daily before the first processed load or according to institutional protocols. Routine testing helps ensure continuous, reliable operation of sterilization equipment.Q: Where is the Bowie Dick Test Pack applicable?

A: Ideal for use in Central Sterile Supply Departments (CSSD), hospitals, clinics, and laboratories, it serves as a critical tool for quality control in any healthcare environment that relies on steam sterilization.Q: What is the process for disposing of the used test pack?

A: After a single use, the test pack should be discarded according to your facility's standard waste disposal protocols. The pack is designed for single-use only and is not reusable.Q: What are the main benefits of using the Bowie Dick Test Pack?

A: It provides immediate, clear visual results, ensuring the effectiveness of your sterilization process. Regular use supports compliance, patient safety, and consistent monitoring of autoclave performance.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Intubation Devices And Accessories Category

DIASPECT HEMOGLOBIN HB ANALYZER

Price 17000 INR / Piece

Minimum Order Quantity : 10 Pieces

Wall Mounted : No

Technology : Broad Spectrum Photometry

Color : White

Usage Type : Handheld/Portable

TULIP 4TH GEN HIV ELISA KIT

Price 4000 INR / Piece

Minimum Order Quantity : 10 Pieces

Wall Mounted : No

Technology : 4th Generation ELISA (Enzyme Linked Immunosorbent Assay)

Color : White plastic, clear or colorless wells

Usage Type : Laboratory, InVitro Diagnostic Use Only

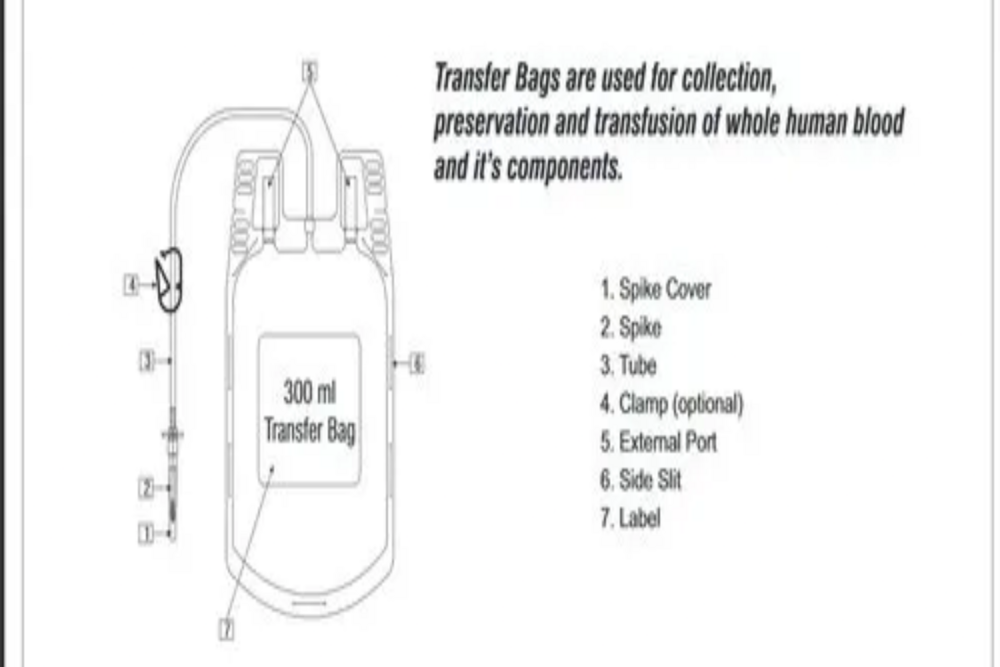

TRANSFER BAG BLOOD BAG

Price 200 INR / Piece

Minimum Order Quantity : 10 Pieces

Wall Mounted : No

Technology : Sterile Closed System

Color : Transparent/Translucent

Usage Type : Single Use Only

CERAPLUS BARRIER EXTENDERS 79402

Price 156 INR / Piece

Minimum Order Quantity : 10 Pieces

Wall Mounted : No

Technology : Skinfriendly adhesive technology

Color : Beige

Usage Type : Singleuse

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free